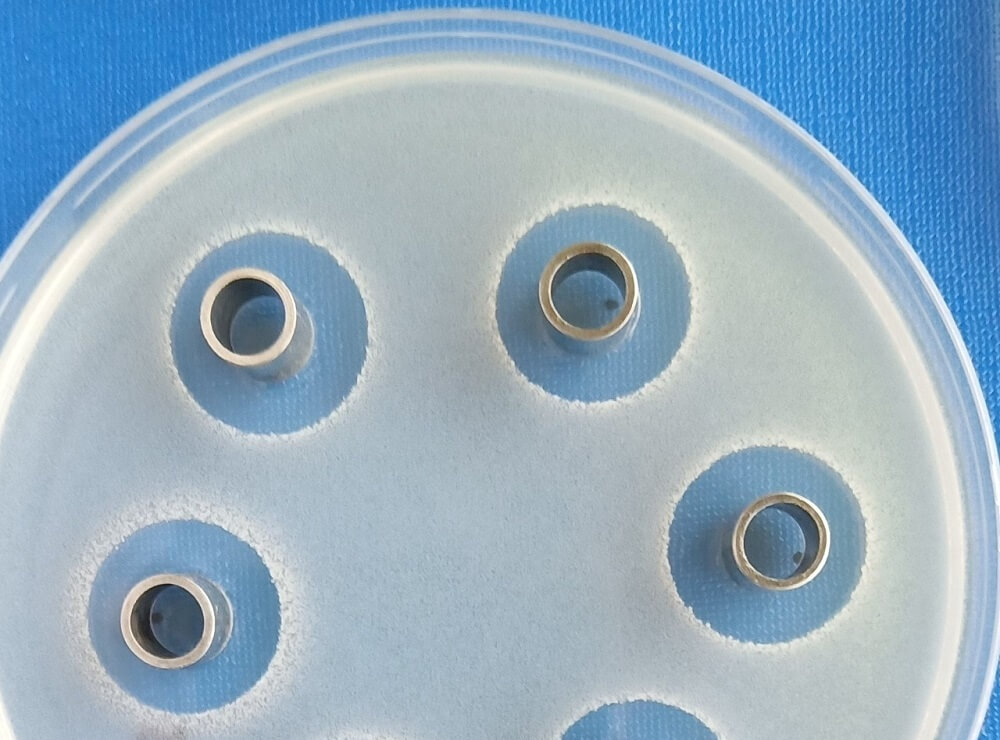

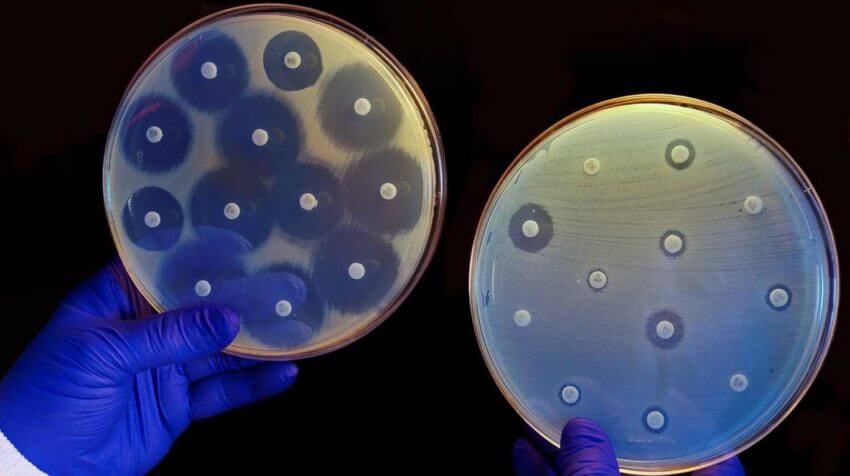

ANTIMICROBIAL TESTS

Preservative Efficacy / Kill rate / Antimicrobial Activity / Biocide Efficacy / Antimicrobial Resistance Test

Preservative / Antimicrobial agents / Biocides are antimicrobial in nature inhibits or kills microbial growth and play important role and controls bioburden levels in product life cycle. Preservative Efficacy Tests are very important to select and optimize preservative concentration in products, which support product shelf life. Antimicrobial resistance test is carried out when antibiotics / antimicrobial agents / Biocides are showing resistance to particular agent and when industrial Hazardous chemical waste is disposed to environment as per Laws.

- Anti-Bacterial / Bactericidal Test

- Anti-Pseudomonas / Pseudomonicidal Test

- Anti-Yeast / Yeasticidal Test

- Anti-Fungal / Fungicidal Test

- Bacterial Sporicidal Test

- Fungal Sporicidal Test

- Anti-Algae / Algicidal Test

- Anti-Mycobacterial / Mycobactericidal Test

- Antibiotic Sensitivity

Disinfectant / Sanitizer Efficacy

Cleaning and disinfection are very important for manufacturing and testing processes to maintain bioburden levels in control state. Disinfectant / Sanitizer / Sterilant agents are very important followed Testing efficacy in vitro methods and using surface templates as per pharmacopoeia and international standards.

Germicidal Efficiency Test

Disinfection devices are based on ultraviolet rays, photocatalytic oxidation and chemical gases / vapour and their Germicidal efficiency test required to prove product performance.

Filter Efficiency Test

Filtration is important in microbial contamination control in environment or product. This is tested by passing small celled bacterial strains to prove filter efficiency.

- Corrosion Test

- Fabric Tests – Antibacterial Tests

- Hand Gloves – Antibacterial Tests

Location

Call Us